Coir, a versatile, natural fiber used in many consumer products, is made from the husks of coconuts using an extraction process called “decorticating.” The coconut is first immersed in water or brine, and then the long fibers are separated from the husk using special “defibering” techniques. Historically, the laborious coir removal process required manual labor. Nowadays, the production process has become largely mechanized, significantly reducing the effort and time involved. The coir extraction process is generally the same regardless of the type of coconut fibers being made. Producers sometimes make minor adjustments to the extraction method to make the natural fibers more coarse or soft to suit consumer products. For example, coir matting is made from rough brown coir, which has a highly abrasive texture to remove and retain debris. On the other hand, the much softer “white coir,” sourced from immature coconuts, is used in delicate products like brushes and netting. If you are interested in buying a coir-based product, having an understanding of the manufacturing process may help you make an informed purchasing decision. This article will directly address often-asked questions about coir: how it’s made, what is the raw material for coir, how do you make coir step by step, what are the properties of coconut coir, and is coir an organic material? Keep on reading to learn interesting information about one of oldest fibers utilized by humans.

“Brown Streaks Modern Door Mats”

- These modern doormats are 18″ x 30″

- UV and ozone resistance helps keep these doormats endure during bright weather

- Easy to clean, simply shake or brush!

Durable Ingredients: Made out of coir, a natural heavy-duty fibrous material extracted from the outer layer of coconut husks, these doormats mean business when it comes to dirt scraping. PVC is also used for the base of this coir doormat, enhancing its overall sturdiness. With both coir and PVC, this outdoor patio mat is put together using quality ingredients.

Avoid Moist Floors: You just cleaned your floor because you are having company over, but it is raining outside and you are worried about them tracking in moisture from outside. The moisture trapping ability of coir makes these walkoff mats incredibly useful for situations or whenever moisture might be involved. This outdoor patio mat is capable of brushing moisture off the bottom of shoes, keeping much of it within the coir fibers of these modern doormats outside where it belongs.

“Casablanca Blue” – Outdoor Coco Mats 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.“Casablanca” Brown – Outdoor Coco Mats 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.“Casablanca” Rubber Cocoa Mat 18″ x 30″ Doormat

Original price was: $34.90.$27.92Current price is: $27.92.“Herringbone” Boot Scrapers 12″ x 13″ Boot Scraper

Original price was: $19.99.$14.99Current price is: $14.99.What Is the Raw Material for Coir?

The raw material for coir is the coconut, or more specifically, the husk of the coconut. The husk is a protective, stringy casing that surrounds the coconut seed. It is composed of two parts: a fibrous layer and a spongy adhesive. The coir fibers that you commonly see in consumer products come from the inner layer of the husk closest to the seed. The pulpy substance that binds these fibers together is known as the coir pith. This pith is primarily used in horticultural and agricultural products, such as seed-growing mediums and soil amendments for gardens. Occasionally, you may have come across products that blend coir with another material. It is important to note that these are not composite ingredients but finished products made from two separate ingredients. If you see a product with “coir” as an ingredient, this typically means the product is made from genuine coconut fibers. The coir extraction process primarily relies on mechanical methods to separate the fibers from the pulp and does not involve additives to alter the natural fiber. However, it is worth mentioning that after the extraction process, the coconut fibers may undergo further processing or treatment to meet specific requirements. However, additives like dyes, if at all, are introduced at later stages of the manufacturing process and do not affect the initial extraction process. You can learn more about the specifics of the coco-fiber extraction process below.

“Bartellet Pears” – a Green Door Mat

- Dries away moisture quickly

- Keeps dirt trapped within coir fibers

- Available in 18” x 30”

Coir Fibers Scrape Away Dirt: Coir is one of the most valued resources for use on doormats because it is a cost-effective material that can fight outdoor contaminants. A coco coir doormat does this by scraping away dirt, mud, and other types of debris off incoming footwear. Coir is a very thick and rough fiber that has a knack for flushing out debris particles. So while they may appear to be simple decorative outdoor mats at first, these coir mats are a great first line of defense in keeping the inside areas of your home clean and free from outdoor dirt.

All Weather Patio Mats: You can leave this coco coir doormat in the outdoors throughout the year. Whether the climate in your area is hot and dry or cold and wet, this doormat can last for a long period of time. Coir does not easily suffer damage from environmental hazards such as moisture, ozone, and UV rays. Moisture is a particular nuisance because when it is left unchecked for prolonged periods of time, it can cause the formation of mold and mildew. Since the fibers of this coco coir doormat can absorb moisture easily, mold and mildew will have a hard time growing on these doormats.

“Field of Red Daisies” – A Welcome Flower Mat 18″ x 30″ Doormat

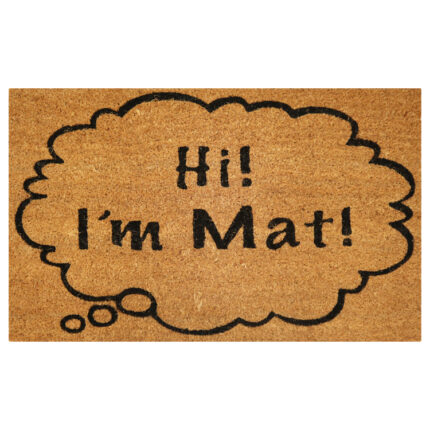

Original price was: $34.90.$24.43Current price is: $24.43.“Hi I’m Mat” 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.“Sunflower Welcome Mats” 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.How Do You Make Coir Step-by-Step?

Coir is made by first harvesting the coconuts and removing the husks, followed by curing the husks. And in the last few steps, the cured husks are milled, and the fibers are separated. It is clear that the process of making coir involves several steps. Let us dive into each one in detail. The very first step in producing coir is harvesting the coconuts that grow in tropical regions of the world. Coconut harvesting is still done by humans in countries like India and Sri Lanka. Harvesters usually climb the trees, which can grow up to 100 feet, and cut the coconuts from the treetops using knives specifically designed for the purpose. If a tree is relatively short, harvesters may use knives attached to the end of bamboo poles to cut down its coconuts. The harvested coconuts must be de-husked before the extraction process begins as the fibers are found inside the coconut. The de-husking process removes the husk from the coconut seed and is done manually by human workers using methods that have been in use for hundreds of years. Human labor is still the most efficient way to de-husk coconuts. While there have been efforts to build mechanical dehuskers, these have largely been unsuccessful at replacing human labor, according to research published in the Journal of Food Engineering.

Once the husks are removed, they are cured using a process called “retting.” Retting is necessary to separate the coir fibers from the pith to make different products like brushes and seed starters. The retting process depends on the maturity of the coconut. If the coconut is mature, the husks are cured in fresh water for three days. Workers typically soak the husks in concrete tanks filled with river water. In countries like India and Sri Lanka, you can still see traditional methods of freshwater retting where the coconut husks are buried along riverbanks. Some small-scale producers may submerge the husks in rivers using nets made from coconut fibers! Unripe coconut husks are cured in seawater or briny water in a prolonged process that can take up to ten months. Just like freshwater retting, saltwater retting involves concrete tanks. Alternatively, coastal-area producers may suspend the husks on briny rivers near the ocean, so that when the tides come, the husks are rinsed in seawater. The retting process decomposes the coconut husks, allowing the fibers to be separated from the coir pith. Once the curing process is complete, the resulting pulp is sent for milling.

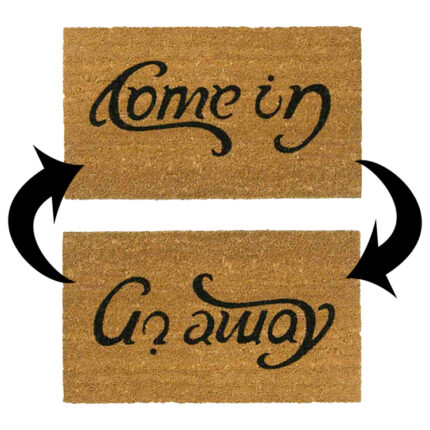

“Come in Welcome Door Mat” 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.“Welcome to our House” Rubber Coir Mat 18″ x 30″ Doormat

Original price was: $34.90.$27.92Current price is: $27.92.Heart Shaped Paws Welcome Mat

Original price was: $34.90 – $58.90.$24.43 – $41.23Current price is: $24.43 – $41.23.The cured pulp has to be milled to completely separate the fibers from the pith. Traditionally, this was done by people with wooden mallets who would beat the decomposed husks to, well, a literal pulp. Nowadays, this process is done by de-fibering machines that have rotating drums like cement churners. Modern machinery has significantly reduced the time it takes to mill retted husks. Once the husks are milled, the coconut fibers can be completely separated and extracted from the pith, which will be used for different types of products. This is the part of the extraction process that is commonly referred to as “decortification.” Once extracted, the fibers undergo a cleaning process to remove any remaining impurities or debris. Afterwards, the fibers are mechanically tumbled and dried under the sun to reduce the moisture content. The dried fibers are then rolled into bales and tied up to be shipped to product manufacturers that make things like coconut matting for consumers. Some producers use machines to compress the fibers into compact cubes to make coir easier to ship. While coir is usually shipped in its natural form, the fibers may be additionally processed to achieve certain qualities depending on the final product. During these additional steps, the fibers may be dyed to make products that have various colorful prints on them. The fibers may also be chemically treated to make them rougher or softer to suit the final product. Not all coir products are additionally processed but those that do are usually labeled accordingly. Finally, the processed coir-fibers are shipped to manufacturers of various coir-based products.

“Red Daisy” – a Flower Door Mat 18″ x 30″ Doormat

Original price was: $34.90.$24.43Current price is: $24.43.“Sunflower Welcome Mats” 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.“Wildflower Meadow” – Welcome Flower Doormat 18″ x 30″ Doormat

Original price was: $34.90.$24.43Current price is: $24.43.Summer “Flower Door Mat” Kit Two 18″ x 30″ Doormats

Original price was: $69.80.$48.86Current price is: $48.86.What Are the Properties of Coconut Coir?

The properties of coconut coir are excellent durability, water-absorption capabilities, resistance to mold and mildew, and the ability to withstand harsh weather conditions. Coir is also widely used in agricultural and horticultural industries as a growth medium due to its biodegradability. Coir is also well-known as a durable fiber that can withstand the elements, microbial activity, and general wear exceptionally well. Coir fibers do not fade under harsh sunlight as rapidly as synthetic variants, making the material perfect for products intended for outdoor use. Coir can withstand constant watering, which makes the material desirable for eco-friendly agricultural and horticultural farms. High durability ensures that coir can be used for extended periods without losing its effectiveness. Another notable property of coir is its high-water absorption capacity. Coir can hold a significant amount of water, making it ideal as a moisture-supply conduit for plants. Moreover, coir is naturally resistant to pests, insects, and fungi. Therefore, coir is a favorable choice for homeowners and gardeners who want to avoid the growth of harmful organisms on matting products they use. The combination of these properties makes coir a highly sought-after material in horticulture, agriculture, landscaping, and other industries. Its water-retention, durability, and pest-resistance characteristics contribute to its widespread usage and popularity as a natural and environmentally friendly alternative.

“Harmonious Garden” Rubber Entrance Mat 18″ x 30″ Doormat

Original price was: $34.90.$27.92Current price is: $27.92.“Minimalist Expression” – Hello Welcome Mats 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.“Nice Underwear Funny Doormat” 18″ x 30″ Doormat

Original price was: $34.90.$24.43Current price is: $24.43.“Warning, Vicious Puppy Inside! Dog Doormats” 18″ x 30″ Doormat

Original price was: $34.90.$26.18Current price is: $26.18.Is Coir an Organic Material?

Yes, coir is an organic material. It is considered an all-natural material as it is derived from a plant source and generally undergoes minimal processing. Coir is biodegradable and renewable, valued for its eco-friendly and sustainable characteristics by consumers and manufacturers alike. The Food and Agriculture Organization of the United Nations recognizes coir as a “sustainable vegetation and erosion control” material that could spearhead an era of eco-friendly “geo textiles.” The typical coir-production process, as mentioned above, does not involve the use of synthetic chemicals or additives during its production. However, certain optional processing methods may introduce chemicals like bleach to the material, but that does not alter the innate nature of coir. Currently, there are no synthetic variants of coir. Coconut fibers used in consumer products are derived solely from natural materials. Treated coir is usually specified as such in product labeling. In various environmentally-sensitive industries such as horticulture, gardening, and soil-amendment, coir is commonly used as an organic alternative to synthetic materials. It is often favored as a substrate or growing-medium for plants due to its natural properties, which include biodegradability. Coir products are recommended over plastic-based synthetic products to reduce the environmental impact of consumption.

Coir stands as a remarkable natural fiber with a multitude of applications and with inherent sustainability. Its extraction process, although laborious, is more eco-friendly than the manufacturing of similar synthetic variants of products. The unique properties of coir, such as high-durability and biodegradability, make coir an excellent material for consumer products, as well as for various industries like agriculture and gardening. The organic nature of coir contributes to its appeal and aligns with the principles of sustainable practices. As we continue to seek alternatives to materials that adversely affect the planet, coir emerges as a clear winner, offering us renewable, eco-friendly, and reliable solutions.